Do you recall (and it’s not too long ago) when companies and authorities too for that matter, simply used to burn much of their waste to dispose of it? Remember all those plumes of toxic smoke that used to belch into the atmosphere?

Thankfully those times are now gone and, as a result, the world is a cleaner, healthier and safer place. Thanks that is to the stringent rules and regulations that have been brought in.

The primary European standard is the European Union Waste Incineration Directive (EU WID) 2000/76 and today all types of waste materials must be disposed of in incinerator technology that is EU WID compliant. These strict compliance regulations are internationally regarded as the ‘Gold Standard’ and although strictly speaking they apply only to those European countries within the EU, many other countries and organisations around the world now strive to match them.

The primary European standard is the European Union Waste Incineration Directive (EU WID) 2000/76 and today all types of waste materials must be disposed of in incinerator technology that is EU WID compliant. These strict compliance regulations are internationally regarded as the ‘Gold Standard’ and although strictly speaking they apply only to those European countries within the EU, many other countries and organisations around the world now strive to match them.

In the UK human cremation does not fall within the guidelines of the EU WID but instead is governed by the Secretary of State Guidance Note: PG 5/6 (2012) which states that all new installations must match the same stringent standards as the EU WID.

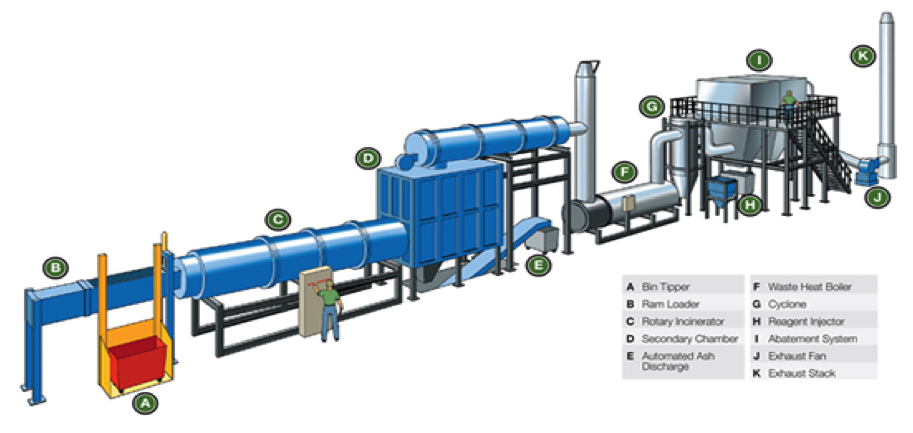

As one of the world’s leading specialists in incineration technology, Matthews Environmental Solutions designs and manufactures a wide range of both standard and bespoke waste incinerators that comply with EU WID regulations. Put simply, in addition to there being a primary incineration chamber where the waste material is destroyed; to become compliant the unit must also incorporate a secondary chamber where the gases generated by the incineration process are also destroyed at a specified temperature and for a specified amount of time. EU WID compliant incinerator technology must also incorporate a heat recovery system to reduce the temperature of the gases before they enter the filter house (sometimes this is also called the flue abatement plant, gas cleaning unit or gas scrubber). Only then, after the gases have been further cleaned are the exhaust fumes allowed to be emitted to atmosphere via the chimney.

As you can imagine, incorporating all this additional incinerator technology means that not only are the waste incinerators bigger in size, but costs are also significantly increased.

It is for this reason that whereas at one time many individual companies, hospitals, laboratories etc all had their own incinerator plant – now the tendency is contract out waste disposal to a centralised waste incinerator facility.

There are one or two exceptions to this directive in Europe – for instance when disposing of clean wood or animal carcass. Generally speaking though, today throughout the whole of Europe all incinerator technology must comply with the EU Waste Incineration Directive.

Having said that, there are still many instances when we manufacture non-compliant incinerators. These are generally destined for overseas countries that are not bound by the EU regulations and where companies and organisations, although in the main they would like to comply with the EU WID, they simply cannot justify or afford the expense.